New era in NAMIBIA DUST-A-SIDE

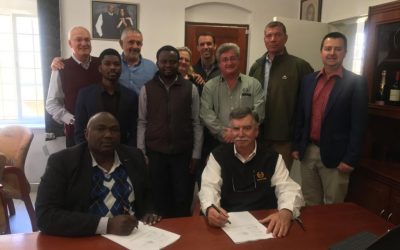

South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development, Infrastructure, Energy and Telecommunication for the provision of Total Dust Management and haul road maintenance services to the Namibian mining industry.

This is a pro-active initiative by Dust-A-Side to establish local partners in areas where it operates. Shitaka will obtain 25% whilst Dust-A-Side occupies a 75% stake in the joint venture agreement.

Owner and Executive Chairman of Shitaka Group, John Akapandi Endjala expressed his happiness with this partnership as his company associates itself with a global leader in offering Dust Management Solutions to the Mining Industry and encouraged the mines to support this partnership as it empowers the local communities, contributing to the growth and sustainability of the Namibian economy.

Having been the president of the chamber of commerce in the SADC region, John Akapandi Endjala, brings a wealth of experience in the Namibian business world and local entrepreneurship. Akapandi as he is known in business circles is a highly accomplished and respected businessman in Namibia.

“This partnership will not only benefit Shitaka financially but most importantly the skills and knowledge as well as exposure that comes with it, which will greatly equip Shitaka’s young team of professionals with international knowledge”.

“We believe this partnership will provide a great opportunity to Shitaka’s shareholders and employees to grow in this industry and be able to participate in other projects in Namibia and other neighbouring countries”.

Dust-A-Side has been a partner of the Namibian mining sector for more than 30 years with their representation based in Swakopmund.

Pierre Grandet, Dust-A-Side General Manger for African Operations, said he is extremely excited at the opportunities that lies ahead of this new partnership.

“This partnership will enable us to cement and expand our footprint outside the South African borders especially in Namibia and will position us as a leader in Total Dust Management in the country”, Pierre said.

“The first step would be, to secure our existing business in Namibia and develop new business together with Shitaka, thus investing in local communities through employment and local supplier database”.

“We know the conditions in Namibia and we have the much-needed expertise to further roll out our Total Dust Management solutions to the rest of the country”, Pierre added.

“We will not only be focusing on mining activities, but we will also be fostering relationships with communities making sure that we add value to the local economy and also give back in areas we operate in”.

Dust-A-Side provides for a safer working environment, better visibility, improved production, water, tyre and fuel savings, less maintenance costs and improved health benefits.

“This partnership will enable us to cement and expand our footprint outside the South African borders especially in Namibia and will position us as a leader in Total Dust Management in the country ”

New era in NAMIBIA DUST-A-SIDE

A NEW ERA FOR DUST-A-SIDE NAMIBIA South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development,...

Dust-a-Side Electra Mining Africa | Video

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

Electra Mining Africa at Expo Centre Nasrec

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

DUST-A-SIDE FOG CANNON TECHNOLOGY

Dust control, if not managed effectively, can disturb mining production and have a serious impact on the operational costs. Dust-A-Side is continuously looking for new methods that could be benencial to any mining operation in terms of managing dust, whether underground or on surface.

FOG CANNON APPLICATIONS

The Fog Cannons can be used to suppress dust in areas where wind plays a major role. The product allows for better coverage of water, specifcally when treating open tip areas where there are no structures in place and when fewer options are available to install static nozzle manifold arrangements.

Fog Cannons come in mobile units that can be moved at different plant tip areas, stockpile, dumps or blasting areas and can be directly interlinked and activated by the control room, radar sensor or by means of remote activation (Blasting Operations excess of 600m).

HOW IT WORKS

Fog Cannons can be installed to operate automatically using radar sensors. Once a vehicle, such as a haul truck, moves into position, ready to tip, the radar sensor detects the moving vehicle and initiates a fan and high-pressure mist system, which are connected and mounted onto the trajectory outlet side of the fog cannon.

The system will automatically switch off after a predetermined time, set from the control panel, once the vehicle has completed the tip and moved away.

Water passes through one misting nozzle at a high pressure, creating a dense mist cloud, which is dispersed across large areas by an industrial-sized fan.

Water is attached to the dust particles to increase their mass and prevent them from floating on air currents. The benefit of using only water is that no danger is posed to mineworkers’ health, supply is affordable and no harsh chemicals are released into the environment.

KEY BENEFITS

• Very effective with capturing breathable airborne dust

• Low-volumes of water compared to low pressure systems

• Evaporation much higher if compared to low pressure system

• Cover large areas (oscillation option as well)

• Can be positioned and installed easily

The performance of these systems can be further improved by adding a product like HydroPlus, which lowers the surface tension of water particles and makes it easier for the water and dust particles to agglomerate, particularly when managing hydrophobic materials such as coal and other fine ores.

“The Fog Cannon Technology has been researched, engineered and tested significantly throughout 2016/2017 to reach the most effective solution available. To date, Dust-A-Side, has rolled out 10 Fog Cannons in operations throughout South Africa and Australia.”

New era in NAMIBIA DUST-A-SIDE

A NEW ERA FOR DUST-A-SIDE NAMIBIA South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development,...

Dust-a-Side Electra Mining Africa | Video

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

Electra Mining Africa at Expo Centre Nasrec

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

DUST-A-SIDE DELIVERING SUSTAINABLE ENERGY SAVINGS TO MINES IN SOUTH AFRICA

The Government Section 12L Energy Savings Tax Incentive has been made accessible to Dust-A-Side customers. Energy saving projects identified and submitted to SANEDI for the Section 12L Tax Incentive are as a result of Dust-A-Side’s DASMetrics haul road performance monitoring and reporting solution.

Dust-A-Side began engaging with its clients regarding the Section 12L Energy Savings Tax Incentive from the beginning of 2016.

The Section12L Tax Incentive on Energy Efficiency Savings Legislation (12L) was introduced on 1 November 2013 by government, aimed at promoting the efficient use of energy to safeguard the country’s security of supply and address environmental concerns.

On an annual basis 12L offers a tax incentive for large energy users who implement appropriate energy efficiency measures where energy performance improvement can be verified and validated by an Measurement and Verification Inspection Body. The tax deduction rate is currently 95 cents per verified kilowatt hour (kWh) of energy

saved – for the relevant year of assessment commencing on or after 1 March 2015. This opportunity to claim tax deductions applies until 1 January 2020.

Dust-A-Side has gained approval from Anglo American to implement the 12L tax incentive at 3 of its mines. ECS (registered and accredited Measurement and Verification Inspection Body) has been appointed by Anglo American to conduct the required verification and validation inspection work for the haul road energy improvement projects as conducted by DAS. The first phase of these projects is for 2016 and are currently being registered by ECS with SANEDI.

The South African National Energy Development Institute (SANEDI) is the organisation tasked with the responsibility of adjudicating, evaluating and supporting the Section 12L Energy Savings Tax Incentive.

Energy and Combustion Services (ECS) is an Energy and Productivity Improvement company delivering energy and emissions management solutions to large industrial and mining customers. ECS is a certified measurement and verification inspection body for energy savings accredited by SANAS and SANEDI.

DASMetrics Dust-A-Side’s Haul Road Condition Monitoring, Reporting and Workflow Management solution developed by Dust-A-Side. Through DASMetrics, Dust-A-Side is able to quantify the reduced diesel/fuel usage of all trucks and equipment on DAS roads.

DASMetrics:

· Auditing – offers a scientific auditing process ensuring

continuous improvement of Haul Road quality

· Workflow Management – allows the user to schedule,

assign and track tasks such as audits and repairs

· Monitoring & Reporting – provides unique processes

and systems to monitor and report on Haul Road

condition and performance

Key benefits:

· Fuel savings CO2 avoidance

· Productivity increase Tyre wear savings

· Water savings Dustiness reduction

· Improved safety

MGM Project Services is Dust-A-Side’s strategic partner responsible for operational consulting on project services for the 12L projects. They are responsible for increasing Dust-A-Side’s footprint, proving DASMetrics’ capabilities and leveraging 12L benefits for each mine site.

Step 1: Identifying savings per mine site through DASMetrics’ measurement and verification reports.

Step 2: Opportunity scope – Operational current state and potential projects are reviewed and identified for implementation

Step 3: These projects are reviewed by ECS who

establishes the potential 12L rebate target for each site.

Step 4: On instruction from the mine ECS registers,

implements and runs the project for the relevant tax

year.

There are five areas which are being reported on:

1. The fuel being avoided due to less rolling defect score (RDS) on a Dust-A-Side treated haul road versus an untreated haul road.

2. The emission reduction on Dust-A-Side treated haul roads due to the improvement of the haul road condition vs untreated roads.

3. The increase in production on Dust-A-Side treated haul roads due to the improvement in haul road condition

4. The reduction in tyre wear as a result of the improved haul road conditions.

5. The reduction in water use when applying the Dust-A-Side product

Step 5: ECS tracks and reviews the project

performance progress and verifies and validates the

project performance at the end of the period. This is

then submitted to SANEDI for review and granting of

the Tax Incentive Certificate.

Step 6: Opportunity scope is conducted for the coming

year which includes road extensions and additional

savings measures in order to improve on 12L benefits

for next period.

DASMetrics Value Report example, the information

below has been taken from a current DASMetrics site.

It is important to note that this extract is from a current

value report that has been validated by ECS who is an

accredited M&V Inspection Body.

Dust-A-Side’s effciency proposal has been introduced to

Anglo American where 7 DASMetrics systems are currently in use. The 2017 proposal for Anglo American has been

approved and these sites will run the full project in 2018

with proposed savings in mind.

Dust-A-Side is the only company in the world to offer this

benefit to its clients, with ECS being the only verification

company concerned with diesel usage in South Africa.

Verification and quantification cannot be done without

Dust-A-Side’s DASMetrics solution.

Monitoring is performed via visual audits. A

specialised DASMetrics handheld device is used by a

trained operator to capture road defects, these are

synchronised to a database. The data is then

integrated, transformed and analysed to produce

reports via a DASMetrics dashboard which is used by

site managers as a haul road performance

management tool

New era in NAMIBIA DUST-A-SIDE

A NEW ERA FOR DUST-A-SIDE NAMIBIA South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development,...

Dust-a-Side Electra Mining Africa | Video

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

Electra Mining Africa at Expo Centre Nasrec

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

DUST-A-SIDE HEROES TAKE PROACTIVE STEPS TO ENSURE SAFETY AT NEW DENMARK COLLIERY

Safety in Mining – Achieving a zero harm target in the mining industry remains a commitment to Dust-A-Side and the broader mining community. One of the ways in which this can be achieved is through each person taking responsibility in being held accountable for their own actions.

In the 40 year history of Dust-A-Side’s existence, no occupational accident has taken place that resulted in a fatality. This is because, Dust-A-Side has a pro-active, rather than reactive Safety Health Environment Quality Community (SHEQC) management approach, where it strives to proactively identify, assess and where possible eliminate all hazards and associated risks by implementing control measures to mitigate risks.

Jerry Sbiloane, Dust-A-Side load haul dumper and tractor operator at New Denmark Colliery, together with his two other colleagues Mandla Qwabe and Enoch Gule were recognised as heroes after they identied a potential safety risk underground.

Jerry recognised a very unsafe condition in the underground section. He reported it and subsequently retracted his fellow employees and other bystanders from the area. Immediately after that, a fall of ground occurred, where they would have been standing that could have resulted in a fatal accident.

Speaking at the celebratory braai held in honour of the Dust-A-Side heroes, Derik Oosthuizen, Dust-A-Side SHEQC Manager said, “We are here today to show you and reiterate that, we take safety seriously and that we appreciate good, proactive behaviour when it comes to identifying unsafe conditions”.

“Safety in the mining area is of utmost importance and what these gentlemen did was indeed a heroic act”, Derik added. “Dust-A-Side is proud to have colleagues who pro-actively take safety into consideration and go out of their way to ensuring safety for themselves and their fellow colleagues”.

Malan Cronje, Dust-A-Side: Operational Manager – Eastern Division, said “It’s wonderful to see that our safety inductions programmes and the sharing of knowledge empowers our colleagues on the ground to be able to identify hazards and potential risks as well as how to handle such situations”.

“Remember, complacency is the snake of the mining industry; as soon as you become complacent, it bites you”, Malan reminded the team. To date, the chamber of mines has recorded over 70 deaths of mine workers who were killed in mine-related accidents.

In the 40 year history of Dust-A-Side’s existence, no occupational accident has taken place that resulted in a fatality. This is because, Dust-A-Side has a pro-active, rather than reactive Safety Health Environment Quality Community (SHEQC) management approach.

New era in NAMIBIA DUST-A-SIDE

A NEW ERA FOR DUST-A-SIDE NAMIBIA South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development,...

Dust-a-Side Electra Mining Africa | Video

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

Electra Mining Africa at Expo Centre Nasrec

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

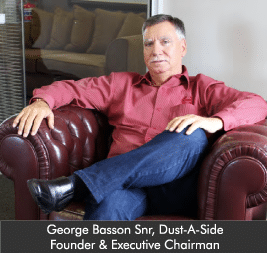

South Africa: 2016 SABITA Award won by George Basson

Dust-A-Side Founder and Executive Chairman, George Bosson Snr has been nominated and after an adjudication process, awarded the prestigious 2016 SABITA Award for Outstanding Achievement in the Sustainable Use of Bituminous Products.

The Southern African Bitumen Association (SABITA) Award is the bituminous products industry’s most

prestigious award.

Congratulations to George Bosson Snr on his tremendous contribution to technology development in the bituminous products industry and his honourable leadership within Dust-A-Side. A pioneer amongst his peers, Mr. Bosson Snr has over 40 years of experience within the industry.

Mr Basson’s concept for dust control on mines has evolved into a value proposition tailored for each mine-site, both strategic and operational, to ensure maximum benefit in dust reduction and therefore contributing towards environmental sustainability at a local and international scale.

The award ceremony is to be held in Cape Town on Tuesday, 4 April 2017 at the River Club in Observatory.

Dust-A-Side – Not Only a Bitumen Specialist

Dust-A-Side has been at the forefront of dust suppression and haul road management for over 40 years offering a wide range of solutions for a dust-free environment, both underground and opencast. With a range of products i.e. Dust-A-Side Product, Hydrotac, Hydrowet,...

New era in NAMIBIA DUST-A-SIDE

A NEW ERA FOR DUST-A-SIDE NAMIBIA South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development,...

Dust-a-Side Electra Mining Africa | Video

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...