New era in NAMIBIA DUST-A-SIDE

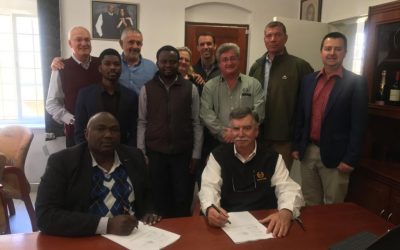

South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development, Infrastructure, Energy and Telecommunication for the provision of Total Dust Management and haul road maintenance services to the Namibian mining industry.

This is a pro-active initiative by Dust-A-Side to establish local partners in areas where it operates. Shitaka will obtain 25% whilst Dust-A-Side occupies a 75% stake in the joint venture agreement.

Owner and Executive Chairman of Shitaka Group, John Akapandi Endjala expressed his happiness with this partnership as his company associates itself with a global leader in offering Dust Management Solutions to the Mining Industry and encouraged the mines to support this partnership as it empowers the local communities, contributing to the growth and sustainability of the Namibian economy.

Having been the president of the chamber of commerce in the SADC region, John Akapandi Endjala, brings a wealth of experience in the Namibian business world and local entrepreneurship. Akapandi as he is known in business circles is a highly accomplished and respected businessman in Namibia.

“This partnership will not only benefit Shitaka financially but most importantly the skills and knowledge as well as exposure that comes with it, which will greatly equip Shitaka’s young team of professionals with international knowledge”.

“We believe this partnership will provide a great opportunity to Shitaka’s shareholders and employees to grow in this industry and be able to participate in other projects in Namibia and other neighbouring countries”.

Dust-A-Side has been a partner of the Namibian mining sector for more than 30 years with their representation based in Swakopmund.

Pierre Grandet, Dust-A-Side General Manger for African Operations, said he is extremely excited at the opportunities that lies ahead of this new partnership.

“This partnership will enable us to cement and expand our footprint outside the South African borders especially in Namibia and will position us as a leader in Total Dust Management in the country”, Pierre said.

“The first step would be, to secure our existing business in Namibia and develop new business together with Shitaka, thus investing in local communities through employment and local supplier database”.

“We know the conditions in Namibia and we have the much-needed expertise to further roll out our Total Dust Management solutions to the rest of the country”, Pierre added.

“We will not only be focusing on mining activities, but we will also be fostering relationships with communities making sure that we add value to the local economy and also give back in areas we operate in”.

Dust-A-Side provides for a safer working environment, better visibility, improved production, water, tyre and fuel savings, less maintenance costs and improved health benefits.

“This partnership will enable us to cement and expand our footprint outside the South African borders especially in Namibia and will position us as a leader in Total Dust Management in the country ”

New era in NAMIBIA DUST-A-SIDE

A NEW ERA FOR DUST-A-SIDE NAMIBIA South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development,...

Dust-a-Side Electra Mining Africa | Video

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

Electra Mining Africa at Expo Centre Nasrec

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

Dust-a-Side Electra Mining Africa | Video

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions.

#dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement

#ElectraMining18 #EMA2018

Electra Mining Africa at Expo Centre Nasrec

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions.

#dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement

#ElectraMining18 #EMA2018

DUST-A-SIDE FOG CANNON TECHNOLOGY

Dust control, if not managed effectively, can disturb mining production and have a serious impact on the operational costs. Dust-A-Side is continuously looking for new methods that could be benencial to any mining operation in terms of managing dust, whether underground or on surface.

FOG CANNON APPLICATIONS

The Fog Cannons can be used to suppress dust in areas where wind plays a major role. The product allows for better coverage of water, specifcally when treating open tip areas where there are no structures in place and when fewer options are available to install static nozzle manifold arrangements.

Fog Cannons come in mobile units that can be moved at different plant tip areas, stockpile, dumps or blasting areas and can be directly interlinked and activated by the control room, radar sensor or by means of remote activation (Blasting Operations excess of 600m).

HOW IT WORKS

Fog Cannons can be installed to operate automatically using radar sensors. Once a vehicle, such as a haul truck, moves into position, ready to tip, the radar sensor detects the moving vehicle and initiates a fan and high-pressure mist system, which are connected and mounted onto the trajectory outlet side of the fog cannon.

The system will automatically switch off after a predetermined time, set from the control panel, once the vehicle has completed the tip and moved away.

Water passes through one misting nozzle at a high pressure, creating a dense mist cloud, which is dispersed across large areas by an industrial-sized fan.

Water is attached to the dust particles to increase their mass and prevent them from floating on air currents. The benefit of using only water is that no danger is posed to mineworkers’ health, supply is affordable and no harsh chemicals are released into the environment.

KEY BENEFITS

• Very effective with capturing breathable airborne dust

• Low-volumes of water compared to low pressure systems

• Evaporation much higher if compared to low pressure system

• Cover large areas (oscillation option as well)

• Can be positioned and installed easily

The performance of these systems can be further improved by adding a product like HydroPlus, which lowers the surface tension of water particles and makes it easier for the water and dust particles to agglomerate, particularly when managing hydrophobic materials such as coal and other fine ores.

“The Fog Cannon Technology has been researched, engineered and tested significantly throughout 2016/2017 to reach the most effective solution available. To date, Dust-A-Side, has rolled out 10 Fog Cannons in operations throughout South Africa and Australia.”

New era in NAMIBIA DUST-A-SIDE

A NEW ERA FOR DUST-A-SIDE NAMIBIA South Africa’s leading dust suppression specialist, Dust-A-Side, has entered into a shareholding agreement with the Shitaka Group, a Namibian owned company which specialises in Property Development,...

Dust-a-Side Electra Mining Africa | Video

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...

Electra Mining Africa at Expo Centre Nasrec

Visit us at Electra Mining Africa at Expo Centre Nasrec from 10 -14 Sept in Hall 5, to learn more about Dust-a-side newest solutions. #dustaside #dustsuppression #miningsolutions #dustcontrol #dustmanagement #ElectraMining18...